Background:

Our customer has an existing test system for remanufactured steering gears for large over-the-road trucks. A test bench system in Canada simulated the drive system of these vehicles.

Challenge:

The customer contracted Scott Industrial Systems to design a new test system for operations located in Mexico. The existing test bench required manual operation and utilized all analog gauges. Everything was measured through gauges and flow control knobs. Operators had to manually change settings for four individual tests on nine different steering gears. This was both time-consuming and created inconsistencies in the overall process.

Methodology:

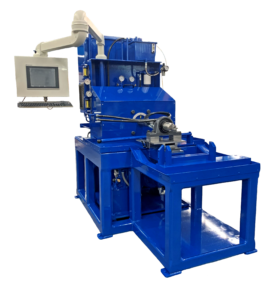

Our engineers created a more intuitive interface where the gauges and controls are automatic. They utilized a PLC/HMI interface, digital flow meters, and pressure sensing devices. Engineers replaced the analog test system with a computer. An operator selects the unit they want to test, and guidelines and procedures display for each test. Bilingual controls change the language of instructions for operation. 30 test values auto-populate for each steering unit. The system implements a new variable frequency drive with a fixed gear pump which uses different flow rates for individual systems. Operating standards for the output force of the steering gears enable up to 58,000 in. pounds of output torque. Steering unit resistance torque for each test is provided by a pressurized rotary actuator built into the test bench.

The new test bench keeps track of every passed and failed test. The operator can download and export that data, review information on parts and serial numbers, and save 50 full test results per day. Test results are then archived for quality control.

Result:

Our solution met the customer’s need for consistency by automating test bench values. The new system is intuitive, with a digital display that lists specific instruction. This new solution also saves time for the operators as all test perameters are preloaded. This helps result in operational efficiencies that maximize operator output and actionable data from the test bench.

Founded in 1948, Scott Industrial are experts in fluid power. We offer design and assembly services as well as training to help customers maintain optimal equipment performance.

To learn more about Scott Industrial Systems’ capabilities visit http://www.scottindustrialsystems.com/. To discuss our efficient and collaborative approach to your project, call 937-233-8146 or e-mail us at sales@scottindustrial.com.