To achieve peak equipment performance, enhance efficiency, and bolster reliability in your operations, partnering with a trustworthy ally is essential.

Leveraging our capabilities ensures we can surpass all your expectations.

We're a partner, using only Moog OEM parts

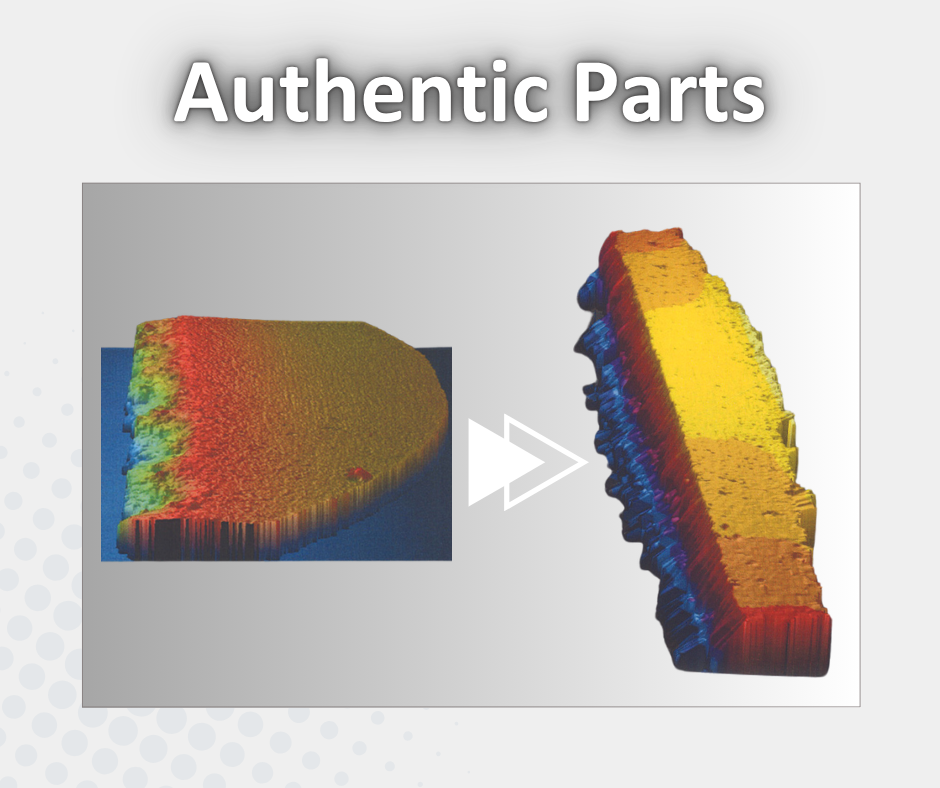

Conduct a full factory failure

analysis and inspection

Can provide a Moog two-year

factory warranty

Can provide re-certification on all servo valve parts

Service Area

- Central Ohio

- Southern Ohio

- Kentucky

- Northern Illinois

- Southern Indiana

- Central West Virginia

- Southern West Virginia

Collaborate

Through close collaboration with you and Moog, we'll determine the

root cause of the failure & recommend system improvements.

Need more detail?

Ask about

MOOG's

Failure Analysis Report.

Recommendation

We can tailor a valve & actuator maintenance program to meet your specific needs while decreasing downtime, minimizing repair costs, & increasing productivity.

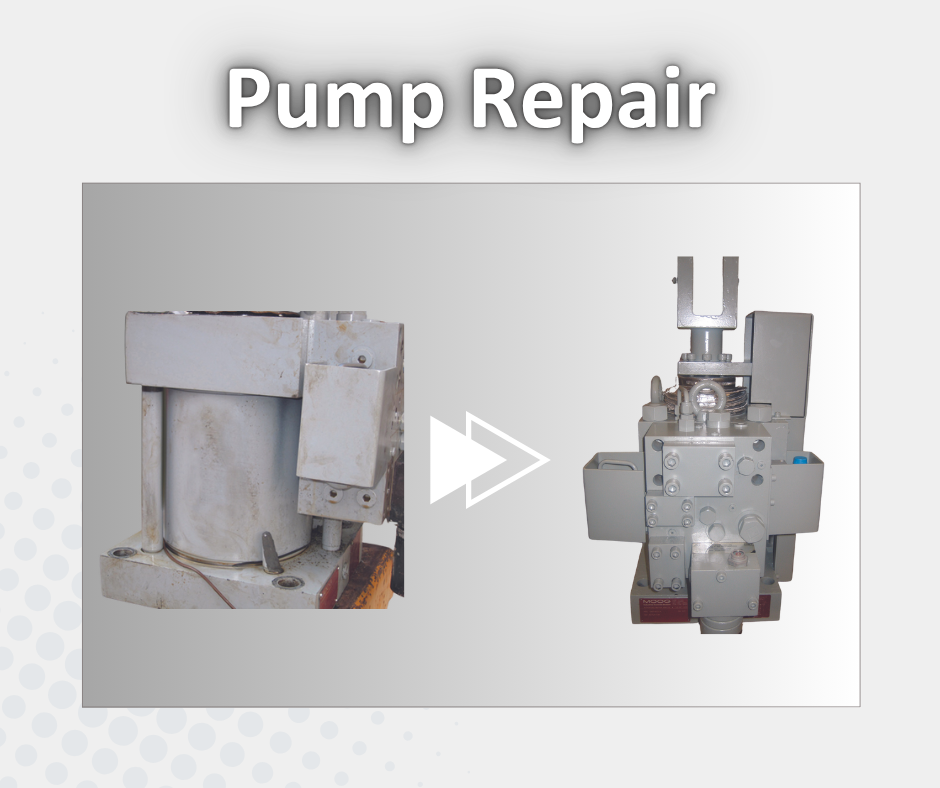

Latest Configuration

Sometimes parts sent in for repair are updated to the latest configuration from Moog, which means often your repaired item leaves the facility better than when originally manufactured.

Scott will ensure your systems are operating at maximum reliability and efficiency.

Inspection Reports

Moog standard inspection reports identify physical damage, contamination, & other observations.

Moog will replace these parts & report any findings that allow us to solve issues with your hydraulic system.

Should your unit be beyond the point of repair, we can quote Moog replacements.