Your

Fluid Power

& Automation

Partner

Your

Fluid Power

& Automation

Partner

Unlock the power of advanced fluid power and automation solutions tailored for industries like manufacturing, material handling, and energy.

Our cutting-edge products and services are designed to boost efficiency, enhance productivity, and deliver reliable performance, helping your operations run smoother and more effectively across the board.

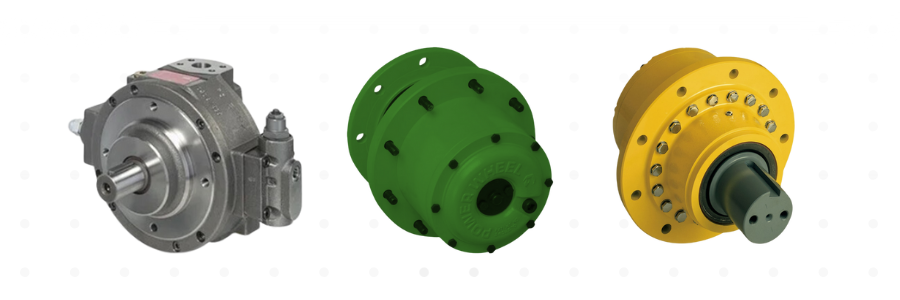

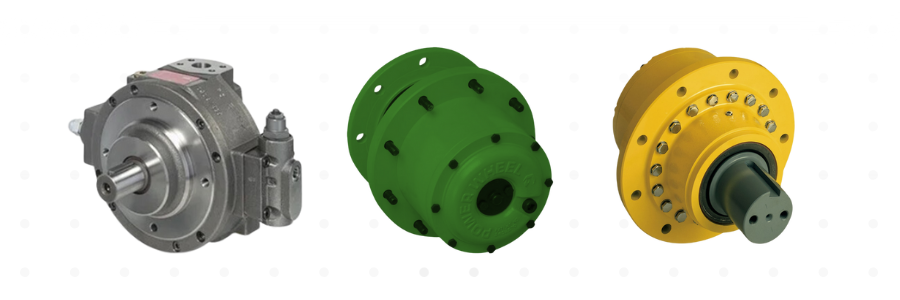

Looking for powerful, efficient control in your machinery?

Mobile hydraulics deliver exactly that, using fluid pressure to transmit power with precision and reliability. Whether you're in construction, agriculture, or transportation, our mobile hydraulic systems provide the robust performance you need to keep your operations running smoothly.

Choose a solution that works as hard as you do!

Harnessing compressed air or gas, pneumatics delivers fast, reliable, and efficient motion for mechanical systems. Perfect for industries like manufacturing, packaging, and robotics, pneumatic solutions ensure precise, controlled movements to keep your operations running smoothly and efficiently.

Let us help you boost productivity with this clean and cost-effective technology.

Protect your hydraulic systems and maximize their performance with top-tier filtration solutions. By effectively removing contaminants, our filtration systems prevent wear, reduce breakdowns, and extend the life of your equipment.

With proper filtration in place, you’ll experience smoother operation, lower maintenance costs, and longer-lasting hydraulic components—ensuring your systems run efficiently and reliably.

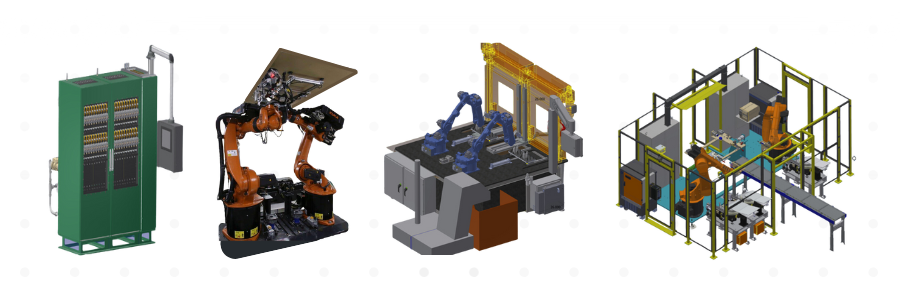

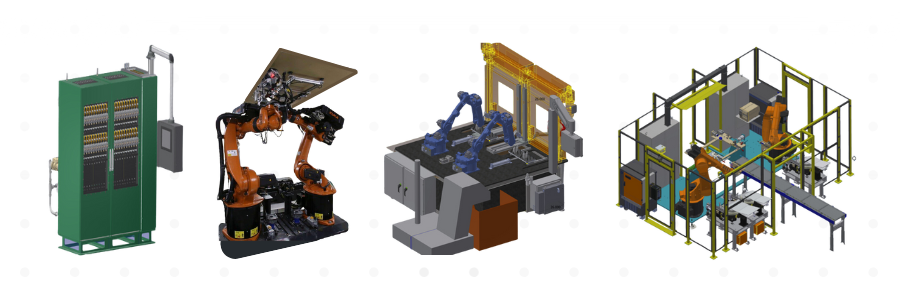

Tap into the power of precision and efficiency with automation. Our advanced hydraulic and pneumatic systems seamlessly integrate with electronic controls to automate your machinery, delivering reliable performance in even the most demanding applications.

Whether you need precise motion, force, or speed control, fluid power automation boosts productivity, reduces downtime, and optimizes your operations for maximum output.

Unlock the power of advanced fluid power and automation solutions tailored for industries like manufacturing, material handling, and energy.

Our cutting-edge products and services are designed to boost efficiency, enhance productivity, and deliver reliable performance, helping your operations run smoother and more effectively across the board.

Looking for powerful, efficient control in your machinery?

Mobile hydraulics deliver exactly that, using fluid pressure to transmit power with precision and reliability. Whether you're in construction, agriculture, or transportation, our mobile hydraulic systems provide the robust performance you need to keep your operations running smoothly.

Choose a solution that works as hard as you do!

Harnessing compressed air or gas, pneumatics delivers fast, reliable, and efficient motion for mechanical systems. Perfect for industries like manufacturing, packaging, and robotics, pneumatic solutions ensure precise, controlled movements to keep your operations running smoothly and efficiently.

Let us help you boost productivity with this clean and cost-effective technology.

Protect your hydraulic systems and maximize their performance with top-tier filtration solutions. By effectively removing contaminants, our filtration systems prevent wear, reduce breakdowns, and extend the life of your equipment.

With proper filtration in place, you’ll experience smoother operation, lower maintenance costs, and longer-lasting hydraulic components—ensuring your systems run efficiently and reliably.

Tap into the power of precision and efficiency with automation. Our advanced hydraulic and pneumatic systems seamlessly integrate with electronic controls to automate your machinery, delivering reliable performance in even the most demanding applications.

Whether you need precise motion, force, or speed control, fluid power automation boosts productivity, reduces downtime, and optimizes your operations for maximum output.

Your

Fluid Power

& Automation

Partner

Unlock the power of advanced fluid power and automation solutions tailored for industries like manufacturing, material handling, and energy.

Our cutting-edge products and services are designed to boost efficiency, enhance productivity, and deliver reliable performance, helping your operations run smoother and more effectively across the board.

Looking for powerful, efficient control in your machinery?

Mobile hydraulics deliver exactly that, using fluid pressure to transmit power with precision and reliability. Whether you're in construction, agriculture, or transportation, our mobile hydraulic systems provide the robust performance you need to keep your operations running smoothly.

Choose a solution that works as hard as you do!

Harnessing compressed air or gas, pneumatics delivers fast, reliable, and efficient motion for mechanical systems. Perfect for industries like manufacturing, packaging, and robotics, pneumatic solutions ensure precise, controlled movements to keep your operations running smoothly and efficiently.

Let us help you boost productivity with this clean and cost-effective technology.

Protect your hydraulic systems and maximize their performance with top-tier filtration solutions. By effectively removing contaminants, our filtration systems prevent wear, reduce breakdowns, and extend the life of your equipment.

With proper filtration in place, you’ll experience smoother operation, lower maintenance costs, and longer-lasting hydraulic components—ensuring your systems run efficiently and reliably.

Tap into the power of precision and efficiency with automation. Our advanced hydraulic and pneumatic systems seamlessly integrate with electronic controls to automate your machinery, delivering reliable performance in even the most demanding applications.

Whether you need precise motion, force, or speed control, fluid power automation boosts productivity, reduces downtime, and optimizes your operations for maximum output.

Our production team is ready to use our extensive raw product inventory to assemble custom gear pumps, gear motors, and directional control valves for your on-demand needs.

Designing and assembling custom manifolds, circuits, pneumatic assemblies, or small AC and DC power units can enhance your productivity and reduce costs.

Scott Industrial Systems

is a leading fluid power distributor that offers a full range of hydraulics, pneumatics, electronic controls, and automation solutions.

For over 75 years, we’ve partnered with top manufacturers to provide high-quality products and maintain an

extensive inventory to meet customer needs.

In addition to distribution,

we design and build custom hydraulic power units, lube systems, pneumatic controls, valve stands, and test stands for industries like agriculture, construction, material handling, and power generation.

With decades of

expertise in automation, we continue to expand our capabilities to serve our customers better.

Experience the SCOTT advantage - where innovation meets reliability.

Scott Industrial Systems

is a leading fluid power distributor that offers a full range of hydraulics, pneumatics, electronic controls, and automation solutions.

For over 75 years,

we’ve partnered with top manufacturers to provide high-quality products and maintain an

extensive inventory to meet customer needs.

In addition to distribution,

we design and build custom hydraulic power units, lube systems, pneumatic controls, valve stands, and test stands for industries like agriculture, construction, material handling, and power generation.

With decades of

expertise in automation, we continue to expand our capabilities to serve our customers better.

Experience the SCOTT advantage - where innovation meets reliability.

Connect with our team.

We're here to help.

Give us a ring or drop us a line.

READY TO GROW YOUR CAREER?

READY TO GROW YOUR CAREER?